Technique behind the Theatre Organ part 7

The previous articles illustrated the overall picture of a theatre organ. The following articles go into more detail, in particular examining the wind supply and the electrical control.

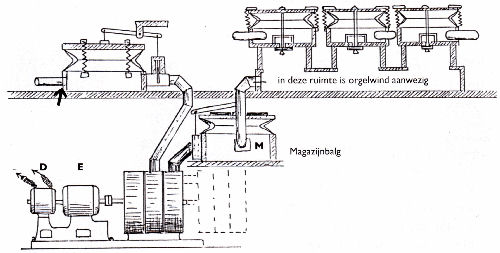

The wind supply is driven by a ‘blower’ consisting of a turbine motor with rotary fans which rotate in one or more wind chambers. The illustration shows a motor with three chambers where the fans provide the wind. More or greater capacity is achieved by adding more chambers. Theatre organs generally run on far higher air pressure than that of church organs.

An organ motor uses a filter to ensure that the wind supplied to the bellows, the windchests etc is as clean as possible.

Dust in the windchests causes problems. It actually works in the same way as a vacuum cleaner but in reverse.

The amount of wind coming from the motor is far too great for the pipes situated on the windchests and the wind pressure is too high. Organ pipes do not all work optimally with the same wind pressure.

Pressure regulators and bellows ensure that the windchests (and therefore the pipes) receive the wind at the correct pressure. The sound is not pure when the pressure is too high.

This is a phenomenon we are familiar with when a recorder is blown with too much force. If the wind pressure is too high the smallest pipes would be blown out of the windchest while the larger heavier pipes would remain standing.

The adjustment of wind pressure and regulators is carried out internally and externally using springs, valve systems and sometimes weights.

It is now time to look at the schematic representation.

Wind machine:

Electric motor (E) drives one or more rotary fans in the chambers to build up the wind pressure. This works in a similar manner to an ordinary fan but with an enormous capacity.

The wind machine must supply enough capacity to allow the entire organ to play without loss of pressure, even at a high volume.

The electric motor in some organs also drives a direct current dynamo (D) for the voltage supply (+/- 16V).

Also present are regulator(s) for the keys and register relays as the pressure is not the same as in the rest of the organ.

Where is all that wind going?

The wind channels (connection path between the turbine and the regulators) are made of wood, metal or plastic. They have the largest diameter possible and as few bends or angles as possible so offering the airflow little resistance.

Main storage bellows:

This ensures that there will always be enough wind capacity available, whether for loud music resulting in high wind consumption or for soft play.

The wind pressure is stored in a storage bellows (M) and then distributed to the regulators who ensure that the wind chests receive the correct pressure.